W-1 Profiler analysis setting function:

1. Maximum temperature and temperature at any time point.

2, Time beyond the specified temperature.

3, The time between two temperature values.

4, The slope between two temperature values.

5, The slope between two time points.

6. Temperature sampling point location name and PCB schematic diagram

7. Setting temperature and transportation speed in reflux furnace and wave peak temperature zone.

8. The time between the horizontal temperature line, the vertical time line and the two time.

9. Mesh editing and zoom display.

10. Simulate curve function, process optimization, date and time of testing.

11. Input of company name, product name and memo information.

12. Choose the direction of printing (horizontal printing and vertical printing).

13, The temperature data report can be exported to Excel for editing.

14. Insert the picture function to make the temperature test point clear at a glance.

15, The instrument can record 20 sets of curves, download data for synchronous charging.

16, Real-time monitoring and instrument recording two working modes.

17, Manual cleaning and software clearance of instrument memory data.

18, Manual, designated time, specified temperature three boot modes.

19, Product database management

20, Equipment database management

21. Solder paste database management

22, PWI process index analysis

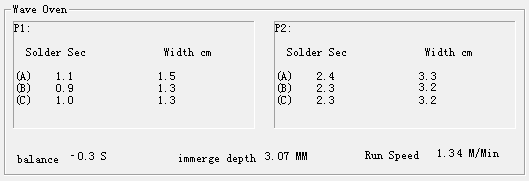

Wave soldering exclusive testing function:

1. Test the peak level function.

2. Test the depth function of immersion tin.

3. Test tin wave height function.

4, test equipment chain speed function

5. Test the time function of immersion tin.

6. Test the function of dip tin width.

7. Test the slope function of preheating zone.

8. Test the highest temperature function in the preheating zone.

Technical indicators:

Model specification:

| TCK1206

|

Test channel:

| 6 channel thermometer

|

Thermocouple:

| Type K

|

Temperature range:

| 0--1000 ℃

|

Temperature accuracy:

| ± 1 ℃

|

Resolution:

| 0.1 ℃ (Full range)

|

Recorded data:

| 80000 points per channel

|

Sampling interval:

| 0.25----600 seconds software settings

|

Charge voltage:

| 5VDC 1000mA |

Working voltage:

| 3.7VDC (built-in rechargeable battery)

|

Instrument size:

| 196 (L) x 82 (W) x 20(H) mm

|

Protection box size:

| 252 (L) x 100 (W) x 30 (H) mm

|

Wingspan width:

| 112------238mm (standard)

|

Communication port:

| RS-232 and USB compatible

|

Analysis software:

| ProfileManager |

The entire series can be equipped with an optional RF wireless transmission module to achieve wireless data transmission!

TCK1206Temperature profiler is a furnace temperature curve testing product independently developed by TOPCITY Electronics Co., Ltd. Its functional characteristics are mainly reflected in the following aspects:

1: Multi channel synchronous measurement: The instrument supports connecting 6 thermocouples, which can synchronously measure the temperature of different key points on the product and comprehensively record the temperature change process.

2: High precision data acquisition: Using high-precision K-type thermocouples and high sampling rates, it can accurately capture rapid and subtle temperature changes, forming smooth and realistic temperature curves.

3: Durable industrial design: Instrument design emphasizes durability and is usually equipped with high-strength insulation boxes that can withstand high temperature environments, protect internal core components, and ensure stable operation under harsh industrial conditions.

4: Powerful data analysis capability: The accompanying software can visually display the collected data in the form of a time temperature curve, and automatically calculate key parameters such as peak temperature, heating/cooling slope, and residence time within a specific temperature range to assist users in process analysis and optimization.

5: Convenient data storage and reporting: The instrument has a large storage capacity and can store 20 sets of temperature curve data. The software can also generate PDF or Excel reports containing test parameters, curve graphs, and interpretation results with just one click, making it easy to archive and trace.

In summary, the TCK1206 furnace temperature tester is a fully functional and high-quality high-precision portable instrument, suitable for industrial fields that require precise control and data analysis of heating processes.